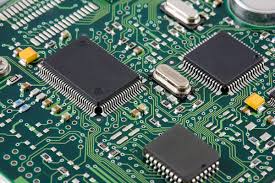

Printed Circuit Boards (PCBs) are the unsung heroes of modern electronics. They power everything from our smartphones to advanced robotic systems, quietly facilitating complex circuitry that drives innovation across various industries. At their core, these intricate boards serve as a foundation for electronic components and enable seamless communication between devices.

Choosing the right manufacturer for PCB needs can greatly influence project success. Look for companies that specialize in various PCB technologies, including printed circuit board transformer. A reliable partner will ensure your designs meet industry standards while also optimizing production efficiency.

Join us on this journey to uncover how technical expertise plays a vital role in creating high-quality printed circuit boards tailored to meet diverse industry needs. Whether you’re an engineer looking for insights or simply curious about the tech behind your gadgets, understanding PCBs could be your gateway into the fascinating realm of electronics.

The Importance of PCB Fabrication and Assembly

PCB fabrication and assembly are crucial steps in the electronics manufacturing process. These processes ensure that electronic components are accurately placed and interconnected, allowing devices to function correctly.

Quality fabrication guarantees durability and performance. It involves etching copper layers onto substrates, creating pathways for electrical signals. Precision during this phase directly impacts the final product’s reliability.

Assembly follows fabrication, where components like resistors and capacitors are mounted onto the PCB. This stage demands meticulous attention to detail; even minor errors can lead to significant malfunctions or failures.

The importance of these processes extends beyond basic functionality. High-quality PCBs enable innovation in various sectors, from consumer electronics to medical devices. As technology advances, so does the demand for robust PCB solutions capable of supporting complex applications seamlessly.

Advanced PCB Solutions: Rigid-Flex and High Frequency PCBs

Rigid-flex PCBs combine the best of both worlds, offering flexibility and durability. These boards integrate rigid and flexible components into a single unit. This design is ideal for compact spaces where traditional circuits may struggle.

High frequency PCBs are engineered to perform at elevated frequencies without signal degradation. Used extensively in telecommunications, these boards ensure efficient data transmission over long distances. They are critical in applications requiring precise timing and minimal interference.

The combination of rigid-flex technology with high-frequency capabilities opens new avenues for innovation. Industries can create more sophisticated devices that take up less space while enhancing performance.

Applications of Advanced PCBs in Telecommunications Industry

Advanced printed circuit boards (PCBs) play a crucial role in the telecommunications industry. Their ability to handle high-frequency signals makes them indispensable for modern communication systems.

Rigid-flex PCBs provide flexibility and compactness, allowing designs that fit snugly into various devices. This adaptability enhances connectivity in smartphones, routers, and satellite communications.

High frequency PCBs support faster data transmission rates. They reduce signal loss and interference, ensuring clearer voice calls and uninterrupted data streaming.

These advanced solutions also enable the development of 5G technology. As networks evolve, robust PCB designs help meet the increasing demand for speed and reliability.

Applications of Advanced PCBs in Robotics Industry

The robotics industry thrives on precision and efficiency, making advanced printed circuit boards (PCBs) essential for modern applications. Rigid-flex PCBs provide flexibility in design while maintaining the necessary structural integrity. This adaptability is crucial when integrating components into compact robotic systems.

High-frequency PCBs play a vital role in enhancing communication between robotic parts. They enable swift data transfer, ensuring that robots can process commands in real-time. Such capabilities are fundamental for autonomous operations where reliability is key.

Technical Expertise in PCB Fabrication and Assembly

Technical expertise in PCB fabrication and assembly is crucial for ensuring high-quality electronic products. Skilled professionals employ advanced techniques to design and manufacture printed circuit boards that meet strict industry standards. Understanding materials, layering, and etching processes is essential. This knowledge helps create reliable connections between components while minimizing signal loss.

An experienced team can optimize designs for functionality and manufacturability. They know how to balance complexity with cost-effectiveness without compromising performance.

Quality control plays a vital role as well. Rigorous testing procedures identify potential failures before they reach the consumer market, reducing costly recalls or repairs later on.

Choosing the Right Manufacturer for Your PCB Needs

Choosing the right manufacturer for your PCB needs is crucial. You want a partner that understands both the technical and practical aspects of printed circuit board fabrication.

Start by evaluating their expertise in advanced solutions like Rigid-Flex and High Frequency PCBs. Check if they have experience in industries relevant to your projects, such as telecommunications or robotics.

Quality control is essential. Look for manufacturers with certifications like ISO 9001, which ensure adherence to high standards throughout production.

Conclusion

Printed circuit boards (PCBs) are the backbone of modern electronics. Their fabrication and assembly require precision and expertise, especially when dealing with advanced solutions like Rigid-Flex and High Frequency PCBs. These innovations cater to industries such as telecommunications and robotics, where performance is critical.